.png)

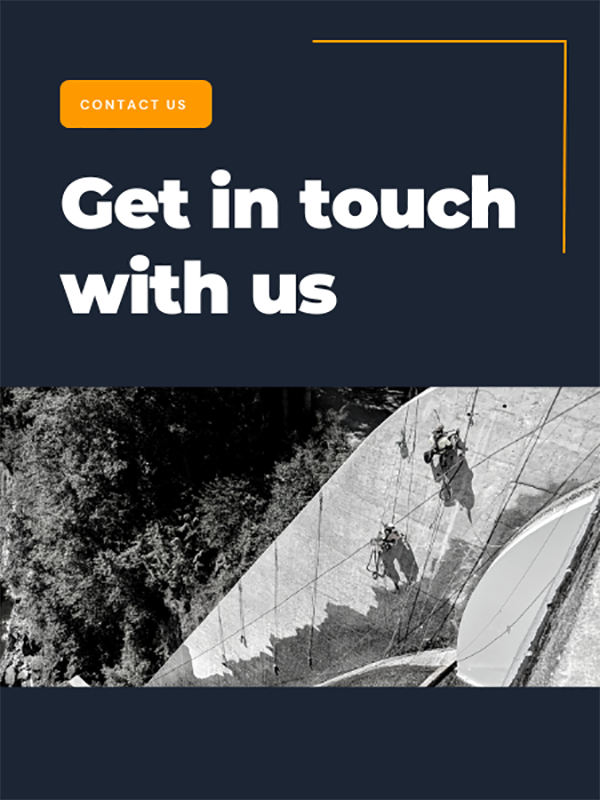

In this case study, we custom engineered an anchor to support two technicians working simultaneously on either side of structure to optimize efficiency within a confined space.

Learn More >SPRAT (Society of Professional Rope Access Technicians) is based in America and aims to promote the safe use of Rope Access within our regulatory bodies here in North America. SPRAT training also consists of three levels of certification, which we host every month in BC only. Our methods of teaching aim to lay out the basics as clearly as possible; while inspiring you to problem solve and to be as efficient as possible. Team collaboration is essential for successful Rope Access technicians and we embody that nature within our Rope Access training.

SPRAT Training >

Our Tower and Climbing Rescue program comes in two parts, Climber 1 and Climber 2. Both are in line and approved by STAC (The Structure, Tower and Antenna Council). This course is meant for technicians who have to climb and work on telecommunication towers. Custom and on-site training is available for this course.

Tower Training >Gain competency in the thorough examination of Personal Protective Equipment (PPE). This Petzl course is perfect for individuals who are responsible for equipment and work at height PPE inspections. But, we encourage all technicians to take this course to gain a better understanding of equipment inspection, which ultimately prevents equipment failure on site.

Petzl PPE Inspection >

We understand that sometimes you need training for a specific work site or structure. Understanding the rescue procedures, protocols, and equipment for a particular job is important and you may not have someone qualified in-house to run this program. Our training team has helped many companies in this scenario with our custom rescue training. These programs can be completed at our facilities or on site.

Contact us >

Pacific Ropes assisted a local bulk terminal with internal steel liner installations. Our multidiscipline team brought an ‘all in one’ solution with rope access welders, riggers, and confined space rescue techs. We were able to lift and install structural components inside the silo.

Our team assisted a local manufacturing facility with various NDE inspections and structural repairs using our NDE Inspectors and Welders to assist with inspections and repairs.

The Pacific Ropes team has carried out repairs to several large stacks, including visual and NDT inspections, and structural welding repairs. Need repairs, inspection, or cleaning inside a 400 foot tall confined space? We’ve done it!

Our team has executed several high profile large diameter penstock / pipe / tunnel inspections and repair projects over the years. Find out why our team is the go to provider for NDE Inspections, Robotic Inspections, Pipe Joint Repair and more.

Need to gain access to a bridge girder, tank, duct work, or other confined space? We can provide the right rescue cover for your specific needs. This includes developing hazard assessments and entry procedures, confined space entry and monitoring, hole watch services, rescue standby, and first aid.

Pacific Ropes was a great asset for our project. They successfully helped with the completion of some very high risk scope involving PT testing of various structural steel connections. Without their assistance, this work would have involved additional rental equipment, numerous scaffold builds, complex fall pro plans, and a large spike in man hours. Pacific Ropes were able to complete the work safely and efficiently while holding themselves to high quality and safety standards that aligned with Kiewit, which ultimately ended up with a substantial cost savings for this scope

Yes, of course we’re always happy to use PR as much as we can; your group is always a treat to work with as you’re very flexible, collaborative, and patient as we know our field is extremely challenging at times. The real value you provided was mitigating our operational impacts inside to users/workers/public as our project backlog grows and my designations change

I wanted to say that it was a pleasure to work with Pacific Ropes for the project and your personnel worked efficiently and adaptably to the challenges that come up with working in such a high profile public space. Please pass on the City’s congratulations for the project and we will keep Pacific Ropes in mind for future projects

Just wanted to say it was an absolute pleasure working with the PacRopes team. Those guys really know their stuff, they were very informative and had great attitudes throughout the challenges we faced. All around awesome guys to work with. We had a good time. Thanks again!

I want to thank you both for your firm’s professionalism and responsiveness. I really appreciate the service that you provided for this job. Your rope techs were extremely hard working and above all safe. They quickly learned how to assist with some aspects of the survey work that I was doing which helped to speed up production, and put in some serious effort on the last day to make sure that our 3D scanner and the operator were safe and able to access some particularly challenging terrain. I look forward to continuing to work with Pacific Ropes on this project

Based on the concept of “doubling up,” Rope Access is a system consisting of ropes and hardware that are attached to a worker in a full body Rope Access harness. Using trained techniques, the worker can utilize this system to go up, down, and around a difficult work location. In addition to this flexibility, a Rope Access Technician can be supported in suspension at their work location all while avoiding any worksite hazards. Below is an illustrative breakdown of the rope access system.

Imagine budgeting a job and being able to reduce scaffolding costs. With rope access, you would be able to eliminate or at the very least, reduce the amount of scaffolding needed.

Think of us like a multi-tool for work at height and confined spaces. Whatever needs to get done, we've got a team who can do it. Check out our services here:

ServicesThere are five components to rope access that each hold their own safety checks and balances in place. Together these five components create a synergy of work at height that is centered around one thing: safety. To read more about these five safety components, click below.

Rope Access SafetyIn Canada, each province differs in how they regulate work at height, including rope access. However, rope access technicians are certified by either IRATA or SPRAT, which are the two rope access associations that have the biggest influence in North America. Companies who choose to use rope access will follow either IRATA or SPRAT regulations. If there are specific rope access regulations within a province, generally, these regulations will defer the specifics back to either IRATA or SPRAT standards.

In Canada, the certifications that are recognized and accepted are IRATA (Industrial Rope Access Trade Association) and SPRAT (Society of Professional Rope Access Technicians). Each certification has three levels that can be obtained. Minimum time experience and rope hours are required before a technician can upgrade to the next level. Each level requires certain amount of days of training and a third party examination. To learn about the different certifications and how training is conducted, please visit our training page!

TrainingDepending on your end goal, it may make more sense to bring in Pacific Ropes as your third party rope access provider or, we can help you build your own rope access team. Or, if can be a combination of both. Contact us to find out more.

Contact usOnce your employee passes their level 1, they will need to work under a L3 rope access supervisor. This requirement is explained in the IRATA and SPRAT regulations, which is reference by provincial regulation in BC and Alberta. But, regulation aside, a level 1 rope tech can maneuver themselves on a rope access system but they do not have the experience or training to be able to perform advance rescues and rigging. Therefore a L3 Supervisor is required on site to manage the overall safety of the rope access work. If you do not have a L3 Supervisor staff member, we can help you hire one through our job postings.

Building internal rope access capability does not have to be complicated. Although there are many details to think about, there are five major areas that you need to consider. IRATA and SPRAT regulation are the guiding documents you need to refer to when putting these five components in place. We also have a Rope Access Management Program that you can utilize to start putting all the pieces in place.

Helping construction and energy industries access hard-to-reach locations with custom work at height solutions