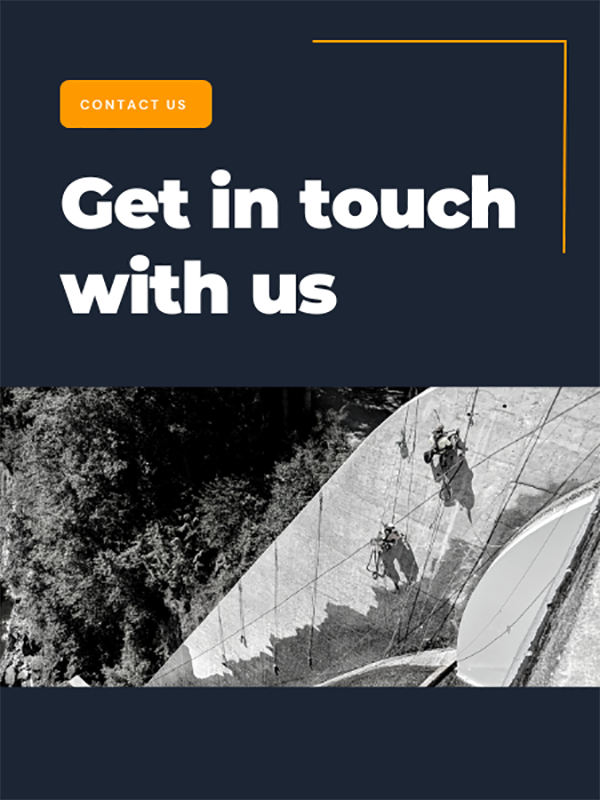

In 2012, the ambitious Port Mann Bridge — the second widest cable-stayed bridge in the world — was finally completed. The process was lengthy and technical, and involved only the best vendors and tradespeople in the province.

With a mandate to reduce closures and the need for bulky equipment on site, the client contacted Pacific Ropes to provide a safer alternative for access and asset installation during this project. Sensitive locations typically require shut downs for safe installation of heavy access equipment such as scaffolding and cranes. Following consultation, Pacific Ropes was able to provide a safer alternative, which would greatly reduce downtime for the highway, and eliminate any potential risk for damages to the bridge structure.

Four specialist rope access and rescue teams were deployed to access the interior and exterior of the bridge’s towers. The teams successfully carried out multiple tasks including electrical cable installation, heavy equipment lifting and installation, stand by rescue services, drilling, anchor installation and industrial guiding.

With a comprehensive work plan, safe work procedures, constant training, and continual risk assessment, it’s no surprise that rope access ended up being a far safer alternative to scaffolding and other methods of access.

In the end, rope access not only increased safety, but decreased operational costs and timelines, making this a textbook use-case for the Pacific Ropes Team.

RESULTS SUMMARY

- Time Savings: 50% (Minimum Estimate)

- Direct Cost Savings: 50% (Minimum Estimate)

- Indirect Cost Savings: No Complete Highway Closures & No Heavy Equipment

To get a complete case study on this project, click below!